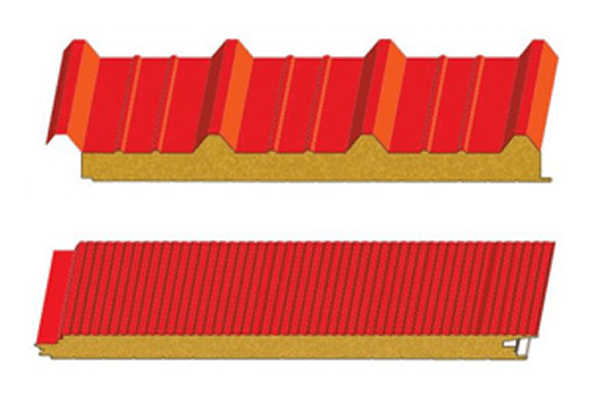

The top and bottom of Rockwool sandwich panel is galvanized pre-painted steel. Core material is rock wool with density at 100kg/m3, the rock wool is upright against the surfaces. There are high strength vesicant between rock wools and surfaces. This product is featured with full anti-firing, more heating and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Reaction to fire

Reaction to fire is the degree in which a material resists combustion, with regard to this, materials are assigned a class (0 through 5), the higher the class, the higher the degree of combustion.

Since the panel consists of two steel facings with a layer of rockwool insulation sandwiched between, then the class 0 refers to the external surfaces, with class 1 referring to the insulation core.

Rock Wool Sandwich Panel Specifications

Thermal performance and strength

At 250C mean temperature thermal conductivity varies between 0.031W/mk and 0.036W.mk depending upon the density of the material.

Acoustic Performance

Our panels offer excellent sound absorption. The Noise reduction Coefficient (NRC) range from 0.80 to 0.95.

Fire Performance

Our panels do not contribute in any way to the spreading of fire. It does not shrink, stretch or deform when exposed to fire. It does not cause smoke or any burning droplets in case of fire. It significantly contributes to improved fire safety.

Resistance to moisture

Water absorption by partial immersion: 0.5kg/m2. Water absorption by full immersion: 10% to 11.5% of weight (tests done as per BS2972)

Storage

To store for long duration, Alfa panels should be stored indoor. If stored outside, the panels should be stacked clear of ground and covered with a securely anchored weather proof sheet. The panels should not be left exposed to weather.

Non Toxic

Alfa panels are not hazardous to health and do not contain asbestos.

Environmental impact

Our panels are free from CFCs, HFCs and HCFs and contain phenol resins within the permissible limits.